HDF vs MDF

Customers regularly get in touch to ask whether we manufacture skirting and architrave from HDF rather than MDF. After doing some digging around online, we realised that the reason we were being asked so much is that another online skirting board supplier makes the following claims:

“HDF is a highly moisture resistant material which is stronger and harder than MDF”

“HDF is far superior compared to standard or premium MDF”

This, unfortunately, is not at all true and is causing confusion for consumers who do not have access to the correct information.

What is HDF?

HDF (High Density Fibreboard/Hardboard), sometimes referred to as HDF wood, is like MDF in that it is a man-made composite panel product that is manufactured from compressed wood fibres. It is a stronger, harder product than MDF with a typical density of up to 900kg/m3. HDF is predominantly used in laminate flooring products where this density is required, though other uses include door skins and underlayment.

HDF is a very thin board, with a typical thickness of 3mm-8mm, and is also often supplied perforated, meaning it is completely inappropriate as a substrate for creating interior mouldings. You may have seen HDF in your home as it is also commonly used as backing panels for furniture- if so you will understand how unsuited this material is for creating skirting boards and architrave!

If you see skirting boards and architrave at thicknesses of 15mm and more advertised as being cut from HDF we would recommend insisting that you see the data sheet or specification for the material being used, as it will definitely not be an HDF. Most likely it will be a dense grade of MDF being sold under the wrong name.

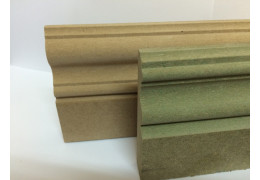

This image demonstrates the difference between various wood panel products- HDF (hardboard) can be seen on the far left, with the MDF on the far right being standard 18mm thickness.

MDF Density

Standard-grade MDF has a typical density of 680kg/m3 – 730kg/m3, whereas the moisture resistant MDF that we use is a premium grade and has a density of 800kg/m3.

The density of MDF is important in the manufacturing of skirting boards and architrave for 2 main reasons:

- The more compact the fibres are, the less likely it is that the MDF will become ‘furry’ when the profile is machined. If MDF does become furry it can lead to imperfections in the paint finish as loose fibres get trapped by the moisture in the primer or paint and harden as it dries.

- Skirting boards need to be as durable as possible to withstand knocks and bumps from furniture and people over time. A denser board will have a greater resistance to damage, meaning it will last longer.

Another visual example of how

Don’t Just Take Our Word for It!

All of the information in this post is correct at the time of writing, and you can confirm any part of this article by visiting the following sources:

https://www.kronospan-worldwide.com/products/medium-density-fibreboard-high-density-fibreboard/

https://walzcraft.com/cabinet-refacing/refacing-materials/#mdfhdf

https://en.wikipedia.org/wiki/Hardboard#cite_note-1

Technical information has been provided by:

https://www.lathamtimber.co.uk/

If you need any more information on this subject please get in touch with our sales team and we will be happy to help!

About the Author

Kieron Miller is the Managing Director of Skirting 4 U and has been working in the skirting board and online retail industry since 2012. Kieron has been using his extensive product knowledge and problem-solving experience to help both trade and private consumers all over the country find the perfect skirting board products for their projects. He continues to innovate new solutions and product ideas as the market continues to grow.

Related products

-

MDF Window Board

Price: £0.00High Quality MDF Bullnose Window Boards Manufactured from hi-spec moisture... -

Edge Plinth Block

Price: £0.00The Edge MDF Plinth Block is designed to create an elegant transition between... -

Georgian MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

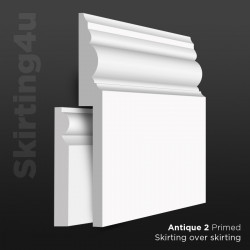

Antique 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Antique MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Colonial MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Edwardian MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Ogee 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Ovolo MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Asmara 3 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Asmara 4 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

S4U 327 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

S4U 330 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Regency MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Victorian MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Victorian 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Edge MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

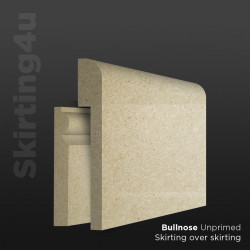

Bullnose MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Mini Bullnose MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Edge 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Square MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Windsor MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Lambs Tongue MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Ripple 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Ripple MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Torus 1 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Ogee MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

S4U 324 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Asmara 5 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

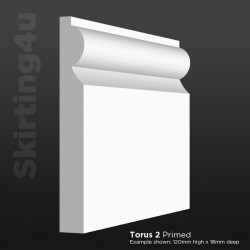

Torus 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Stepped MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Square Groove 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Chamfer MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Marlie MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Roux MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Square Groove MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Edge Groove MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Bullnose Groove MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

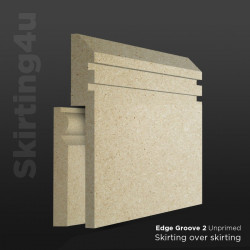

Edge Groove 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

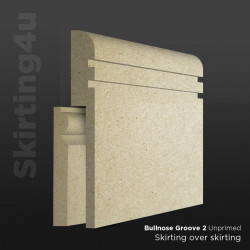

Bullnose Groove 2 MDF Skirting Board Cover (Skirting Over Skirting)

Price: £0.00DELIVERY TIMES Express Delivery - 2 WORKING DAYS Standard Delivery – 5... -

Antique MDF Skirting Board

Price: £0.00The Antique Skirting Board is very traditional in its styling, and... -

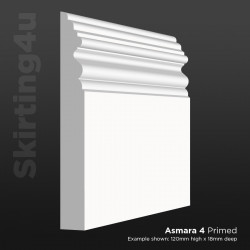

Asmara 4 MDF Skirting Board

Price: £0.00The Asmara 4 Skirting Board is an intricate homage to classical period... -

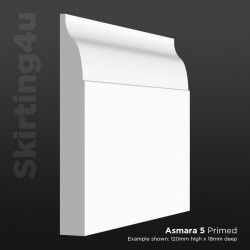

Asmara 5 MDF Skirting Board

Price: £0.00The Asmara 5 Skirting Board seamlessly brings together elegance and... -

Skirt4u 324 MDF Skirting Board

Price: £0.00The design of our S4U 324 profile is based upon the ever-popular Torus... -

Skirt4u 327 MDF Skirting Board

Price: £0.00The 327 design is something of a departure from traditional skirting board... -

Skirt4u 330 MDF Skirting Board

Price: £0.00Our 330 skirting board brings together the best elements of our 327 and 324... -

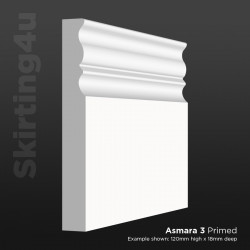

Asmara 3 MDF Skirting Board

Price: £0.00The Asmara 3 is the perfect statement skirting board design. Extremely bold... -

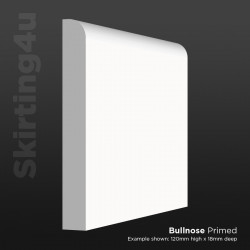

Bullnose MDF Skirting Board

Price: £0.00Bullnose Skirting is widely used by both trade professionals and private... -

Bullnose Groove MDF Skirting Board

Price: £0.00Our Bullnose Groove Skirting Board is a modern profile that is a great... -

Bullnose Groove 2 MDF Skirting Board

Price: £0.00Our Bullnose Groove 2 Skirting Board is a modern take on the classic... -

Chamfer MDF Skirting Board

Price: £0.00Chamfer skirting remains as popular today as ever. The simplicity of the... -

Colonial MDF Skirting Board

Price: £0.00Our Colonial Skirting Board is a replica of a design that was common in the... -

Edge MDF Skirting Board

Price: £0.00The Edge Skirting Board is from the same ‘family’ of designs the Chamfer... -

Edge 2 MDF Skirting Board

Price: £0.00Our Edge 2 Skirting Board (sometimes referred to as ‘scotia’) is a minimal... -

Edge Groove MDF Skirting Board

Price: £0.00The Edge Groove Skirting Board is the regular Edge design with the addition... -

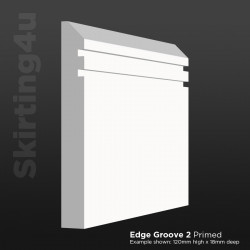

Edge Groove 2 MDF Skirting Board

Price: £0.00The Edge Groove 2 is a skirting board design that brings together the most... -

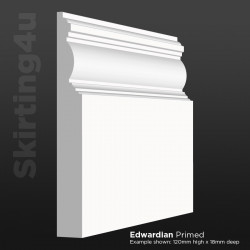

Edwardian MDF Skirting Board

Price: £0.00Our Edwardian Skirting Board design is an homage to styles widely used in... -

Georgian MDF Skirting Board

Price: £0.00Our Georgian Skirting Board is inspired by interior moulding designs used... -

MDF Lambs Tongue Skirting Board

Price: £0.00The Lambs Tongue Skirting Board is a widely-known style and is something of... -

Marlie MDF Skirting Board

Price: £0.00Marlie is a skirting board design that is exclusive to Skirting 4 U. It is... -

Mini Bullnose MDF Skirting Board

Price: £0.00Mini Bullnose skirting board is sometimes referred to as ‘Pencil Round’. It... -

Ogee MDF Skirting Board

Price: £0.00Ogee skirting board has really stood the test of time and remains a firm... -

Ogee 2 MDF Skirting Board

Price: £0.00Ogee 2 skirting board has been introduced to offer an alternative to the... -

Regency MDF Skirting Board

Price: £0.00Regency skirting board is not too dissimilar to the Ogee style in terms of... -

Ovolo MDF Skirting Board

Price: £0.00Ovolo skirting board is another profile that is widely known and sought... -

Ripple MDF Skirting Board

Price: £0.00Our Ripple skirting board is very different to almost all other skirting in... -

Ripple 2 MDF Skirting Board

Price: £0.00The Ripple 2 is very much a statement moulding. Being extremely bold in its... -

Roux MDF Skirting Board

Price: £0.00Roux is a skirting board design that is exclusive to Skirting 4 U. Since it... -

Square MDF Skirting Board

Price: £0.00Square skirting board continues to be hugely popular with both private and... -

Square Groove MDF Skirting Board

Price: £0.00Square Groove skirting board is another modern profile that has remained... -

Square Groove 2 MDF Skirting Board

Price: £0.00Square Groove 2 skirting board is by far and away the most popular modern... -

Torus 1 MDF Skirting Board

Price: £0.00Our Torus skirting board is an absolute classic MDF moulding design.... -

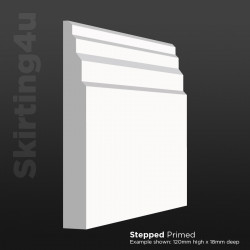

Stepped MDF Skirting Board

Price: £0.00Stepped skirting board is a visually striking design that is a great choice... -

Victorian MDF Skirting Board

Price: £0.00Our Victorian skirting board design is manufactured to sympathetically... -

Torus 2 MDF Skirting Board

Price: £0.00Torus skirting boards are by far the most commonly purchased profile we... -

Victorian 2 MDF Skirting Board

Price: £0.00Our Victorian 2 profile is a second variation of a skirting board design... -

Windsor MDF Skirting Board

Price: £0.00Windsor Skirting Board is one of our more exclusive profiles. It is popular... -

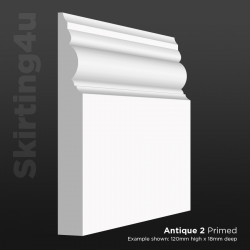

Antique 2 MDF Skirting Board

Price: £0.00The Antique 2 Skirting Board profile is a less complex version of our... -

Bullnose Groove MDF Architrave

Price: £0.00Our Bullnose Groove architrave is a contemporary design that is perfect for... -

Bullnose Groove 2 MDF Architrave

Price: £0.00Our Bullnose Groove 2 architrave is a modern take on the classic Bullnose... -

Bullnose MDF Architrave

Price: £0.00Bullnose architrave is widely used and is one of our more popular profiles.... -

Edge MDF Architrave

Price: £0.00The edge architrave is similar to the Chamfer profile, with a smaller bevel... -

Edge 2 MDF Architrave

Price: £0.00Our Edge 2 architrave (sometimes referred to as ‘scotia’) is a bold... -

Edge Groove MDF Architrave

Price: £0.00The Edge groove architrave is the regular Edge design with the addition of... -

Edge Groove 2 MDF Architrave

Price: £0.00The Edge Groove 2 is a design that brings together the most striking... -

Marlie MDF Architrave

Price: £0.00Marlie architrave is a design that is exclusive to Skirting 4 U. It is a... -

Mini Bullnose MDF Architrave

Price: £0.00Mini Bullnose architrave is sometimes referred to as ‘Pencil Round’ or... -

Ripple MDF Architrave

Price: £0.00Our Ripple architrave is very different to almost all other architrave in... -

Ripple 2 MDF Architrave

Price: £0.00The Ripple 2 is very much a statement architrave. Being extremely bold in... -

Square MDF Architrave

Price: £0.00Square architrave continues to be hugely popular with both private and... -

Square Groove MDF Architrave

Price: £0.00Square Groove architrave is another modern profile that has remained... -

Square Groove 2 MDF Architrave

Price: £0.00Square Groove 2 architrave is by far and away the most popular modern... -

Torus 1 MDF Architrave

Price: £0.00Our Torus 1 architrave is an absolute classic. It is extensively used... -

Antique MDF Architrave

Price: £0.00The intricate detailing in our Antique Architrave creates the perfect... -

Asmara 3 MDF Architrave

Price: £0.00The Asmara 3 Architrave, with its bold styling and clean lines is very much... -

Colonial MDF Architrave

Price: £0.00Our Colonial architrave is a replica of a design that was common in the... -

Regency MDF Architrave

Price: £0.00Regency architrave is not too dissimilar to the Ogee style in terms of... -

Skirt4U 327 MDF Architrave

Price: £0.00The 327 design of architrave is something of a departure from traditional... -

Skirt4U 330 MDF Architrave

Price: £0.00Our 330 architrave brings together the best elements of our 327 and 324... -

Antique 2 MDF Architrave

Price: £0.00The Antique 2 Architrave profile is a less complex version of our Antique... -

Asmara 4 MDF Architrave

Price: £0.00The Asmara 4 Architrave is an intricate homage to classical period design.... -

Asmara 5 MDF Architrave

Price: £0.00The Asmara 5 Architrave has a contemporary styling that is a seamless blend... -

Chamfer MDF Architrave

Price: £0.00Chamfer architrave is a moulding in which its clean-cut yet elegant... -

Edwardian MDF Architrave

Price: £0.00Our Edwardian architrave design is an homage to styles widely used in homes... -

Georgian MDF Architrave

Price: £0.00Our Georgian architrave is inspired by architrave designs used throughout... -

Lambs Tongue MDF Architrave

Price: £0.00The Lambs Tongue architrave is a widely-known style and is something of a... -

Ogee MDF Architrave

Price: £0.00Ogee architrave has really stood the test of time and remains a firm... -

Ogee 2 MDF Architrave

Price: £0.00Ogee 2 architrave has been introduced to offer an alternative to the... -

Ovolo MDF Architrave

Price: £0.00Ovolo architrave is another profile that is widely known and sought after... -

Roux MDF Architrave

Price: £0.00Roux is an architrave design that is exclusive to Skirting 4 U. Since it... -

Skirt4U 324 MDF Architrave

Price: £0.00The design of our S4U 324 profile is based upon the ever-popular Torus... -

Torus 2 MDF Architrave

Price: £0.00The Torus architrave is by far the most commonly purchased profile we... -

Victorian MDF Architrave

Price: £0.00Our Victorian architrave design is manufactured to sympathetically... -

Victorian 2 MDF Architrave

Price: £0.00Our Victorian 2 profile is a second variation of an architrave design that... -

Windsor MDF Architrave

Price: £0.00Windsor architrave is one of our more exclusive, decorative architrave... -

Stepped MDF Architrave

Price: £0.00Stepped architrave is a visually striking design that is a great choice if... -

Torus 1 MDF Skirting Cover SAMPLE

Price: £2.50

Related posts

-

Moisture Resistant MDF- Is It Always Green?

Posted in: Materials & Product Specifications06/22/201622991 viewsMoisture resistant MDF is often green in colour, but not always. This article explains why some moisture resistant...Read more

Moisture Resistant MDF- Is It Always Green?

Posted in: Materials & Product Specifications06/22/201622991 viewsMoisture resistant MDF is often green in colour, but not always. This article explains why some moisture resistant...Read more -

What is MDF?

Posted in: Materials & Product Specifications09/19/20168202 viewsSkirting 4 U manufacture skirting and architrave from the best available MR (moisture resistant) MDF. This blog...Read more

What is MDF?

Posted in: Materials & Product Specifications09/19/20168202 viewsSkirting 4 U manufacture skirting and architrave from the best available MR (moisture resistant) MDF. This blog...Read more -

Oak Skirting Boards & Architrave: FAQ’s about Solid Oak Wood

Posted in: Materials & Product Specifications10/01/20196133 viewsEverything you need to know about the American White Oak that we use to manufacture skirting boards and architrave.Read more

Oak Skirting Boards & Architrave: FAQ’s about Solid Oak Wood

Posted in: Materials & Product Specifications10/01/20196133 viewsEverything you need to know about the American White Oak that we use to manufacture skirting boards and architrave.Read more -

Finger Jointed Pine - The Best Softwood for Skirting Boards?

Posted in: Materials & Product Specifications03/31/20219123 viewsWidely used in the USA and Canada, many people in the UK have not heard of finger jointed pine. In this article we...Read more