How to Measure and Cut a Skirting Board for an External Wall Joint by Bisecting

In this guide, we will showcase how to measure and cut a skirting board for an internal wall joint by bisecting an angle. We have included a step by step guide and a video below:

When fitting skirting board you may come across instances where you need to cut boards to fit external angles which are not 90 degrees. This guide is designed to show you how to calculate the required angle for each cut, as well as making the cuts on a mitre saw.

To

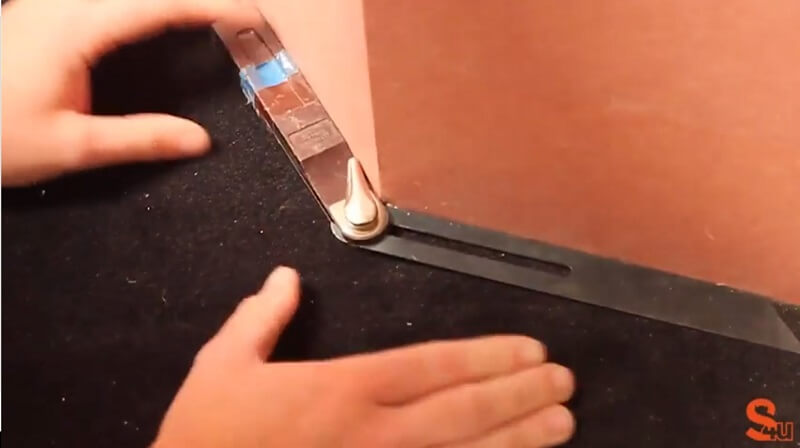

Find the angle with a sliding bevel

We’re essentially trying to work out the value of half of the angle. The reason for this is that you need to make two cuts on the two pieces of skirting which fit together to create the whole angle.

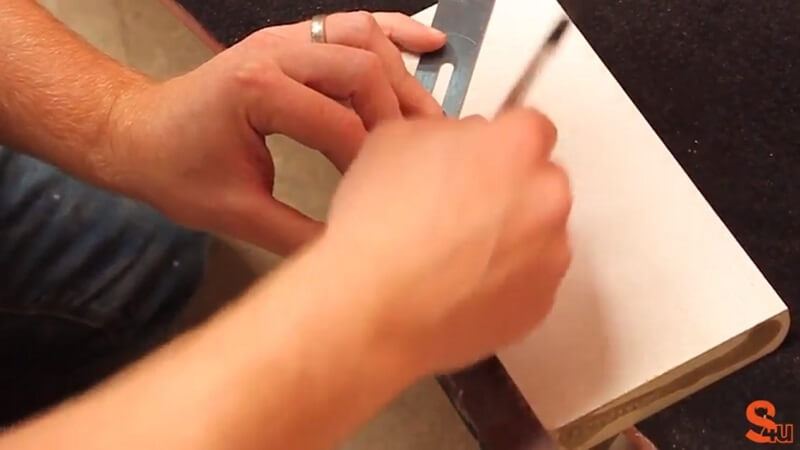

Once you have the angle locked into place, using a pencil transfer this angle to either scrap wood or a skirting board offcut. To transfer the known angle to the offcut, place the bevel onto the offcut so that the handle of the bevel is flush with the bottom edge of the offcut. Then draw along the metal edge with the pencil (see image). This should leave a line from the bottom edge of the offcut to the top and should look like the angle you are trying to replicate.

Mark bevel angle on skirting board offcut

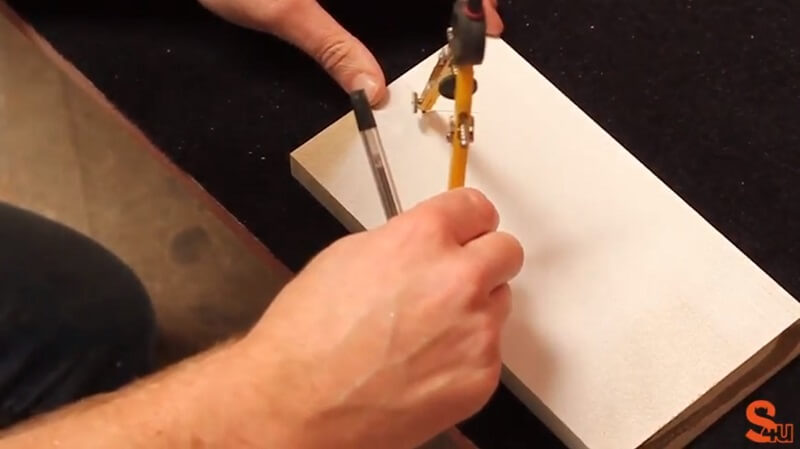

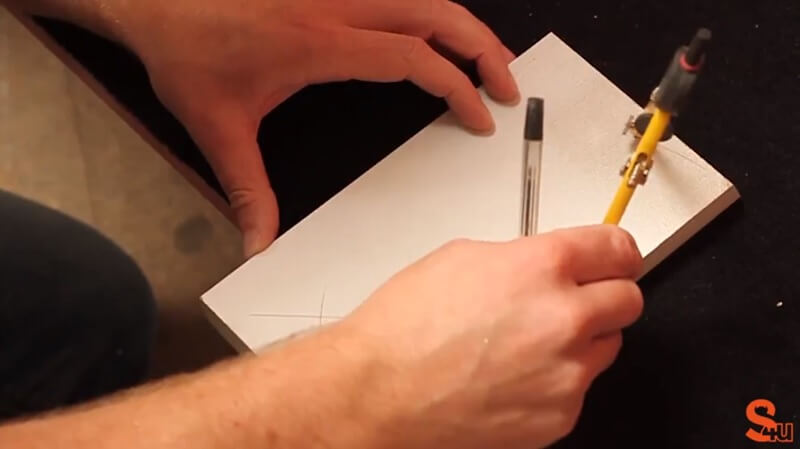

Once you have this marking drawn out, the next stage is to add further markings to calculate the angle for cutting the MDF skirting. Using a compass insert a pen or pencil and extend the arms to roughly 50

Mark arc on the drawn line

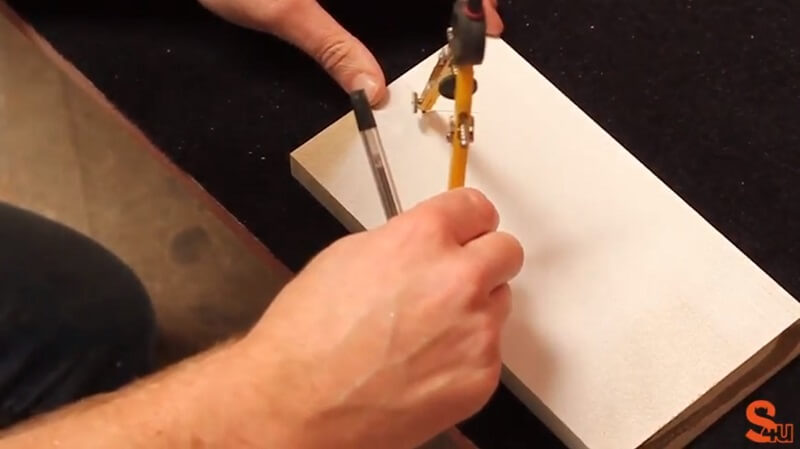

Mark opposite angle on opposite side

The final set of arcs are used to work out the

Marking the first bisect arc

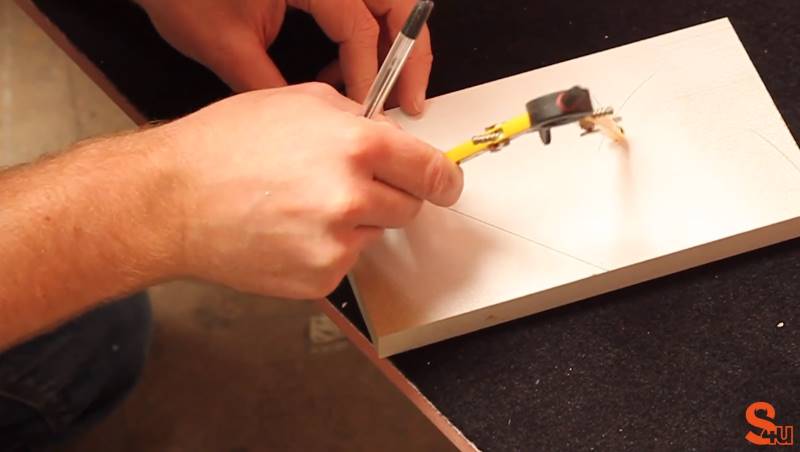

Marking the second bisect arc

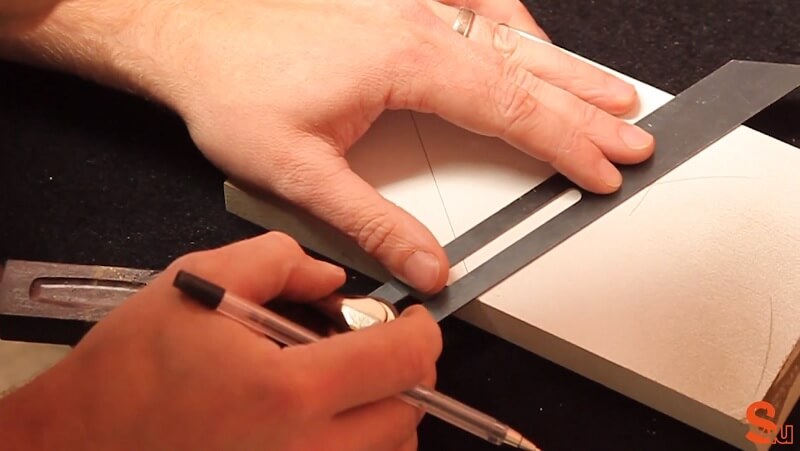

Using either a rule or the metal edge of the sliding bevel, draw a line from the base of the line (from the sliding bevel) to the middle of the

Marking the

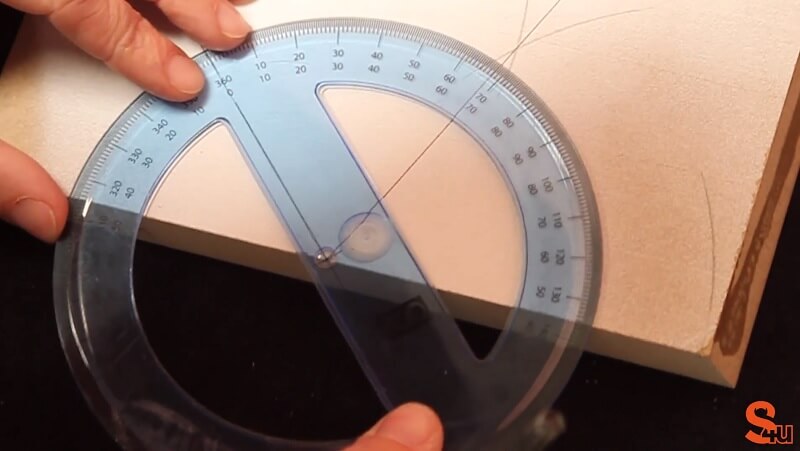

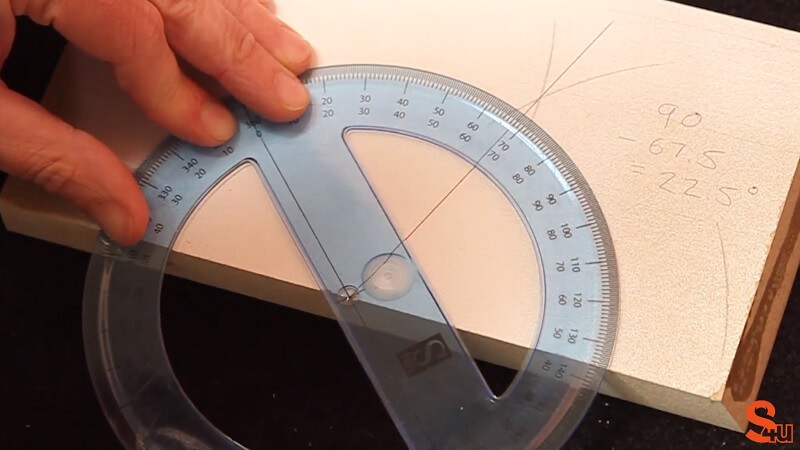

To work out the angle you require you will need a protractor, place the protractor with 0 degrees across the first line we drew from the bevel. The

Place protractor on initial marking

Calculation of

To make the cuts in this case you will need to set your mitre saw to 22.5 degrees. Using offcuts of skirting and cut it at the first angle, then set the mitre to the same degrees but in the opposite direction. You can then put them into position on the wall to check if they are correct. If you’re happy you can then make the final cuts on the pieces of skirting board.

Cut

Test first piece to check

Cut

Final Joint complete

About the Author

Kieron Miller is the Managing Director of Skirting 4 U and has been working in the skirting board and online retail industry since 2012. Kieron has been using his extensive product knowledge and problem-solving experience to help both trade and private consumers all over the country find the perfect skirting board products for their projects. He continues to innovate new solutions and product ideas as the market continues to grow.

Related products

-

Antique MDF Skirting Board

Price: £0.00The Antique Skirting Board is very traditional in its styling, and... -

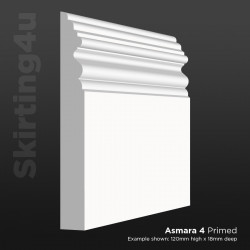

Asmara 4 MDF Skirting Board

Price: £0.00The Asmara 4 Skirting Board is an intricate homage to classical period... -

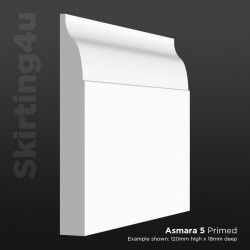

Asmara 5 MDF Skirting Board

Price: £0.00The Asmara 5 Skirting Board seamlessly brings together elegance and... -

Skirt4u 324 MDF Skirting Board

Price: £0.00The design of our S4U 324 profile is based upon the ever-popular Torus... -

Skirt4u 327 MDF Skirting Board

Price: £0.00The 327 design is something of a departure from traditional skirting board... -

Skirt4u 330 MDF Skirting Board

Price: £0.00Our 330 skirting board brings together the best elements of our 327 and 324... -

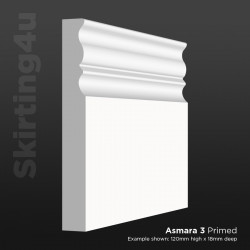

Asmara 3 MDF Skirting Board

Price: £0.00The Asmara 3 is the perfect statement skirting board design. Extremely bold... -

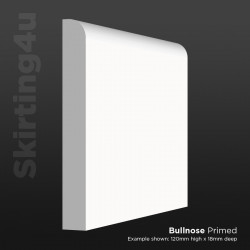

Bullnose MDF Skirting Board

Price: £0.00Bullnose Skirting is widely used by both trade professionals and private... -

Bullnose Groove MDF Skirting Board

Price: £0.00Our Bullnose Groove Skirting Board is a modern profile that is a great... -

Bullnose Groove 2 MDF Skirting Board

Price: £0.00Our Bullnose Groove 2 Skirting Board is a modern take on the classic... -

Chamfer MDF Skirting Board

Price: £0.00Chamfer skirting remains as popular today as ever. The simplicity of the... -

Colonial MDF Skirting Board

Price: £0.00Our Colonial Skirting Board is a replica of a design that was common in the... -

Edge MDF Skirting Board

Price: £0.00The Edge Skirting Board is from the same ‘family’ of designs the Chamfer... -

Edge 2 MDF Skirting Board

Price: £0.00Our Edge 2 Skirting Board (sometimes referred to as ‘scotia’) is a minimal... -

Edge Groove MDF Skirting Board

Price: £0.00The Edge Groove Skirting Board is the regular Edge design with the addition... -

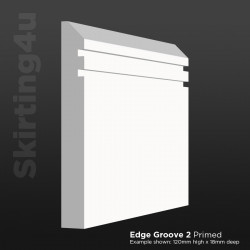

Edge Groove 2 MDF Skirting Board

Price: £0.00The Edge Groove 2 is a skirting board design that brings together the most... -

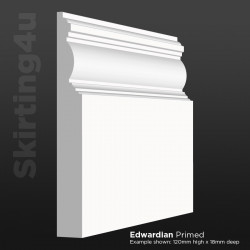

Edwardian MDF Skirting Board

Price: £0.00Our Edwardian Skirting Board design is an homage to styles widely used in... -

Georgian MDF Skirting Board

Price: £0.00Our Georgian Skirting Board is inspired by interior moulding designs used... -

MDF Lambs Tongue Skirting Board

Price: £0.00The Lambs Tongue Skirting Board is a widely-known style and is something of... -

Marlie MDF Skirting Board

Price: £0.00Marlie is a skirting board design that is exclusive to Skirting 4 U. It is... -

Mini Bullnose MDF Skirting Board

Price: £0.00Mini Bullnose skirting board is sometimes referred to as ‘Pencil Round’. It... -

Ogee MDF Skirting Board

Price: £0.00Ogee skirting board has really stood the test of time and remains a firm... -

Ogee 2 MDF Skirting Board

Price: £0.00Ogee 2 skirting board has been introduced to offer an alternative to the... -

Regency MDF Skirting Board

Price: £0.00Regency skirting board is not too dissimilar to the Ogee style in terms of... -

Ovolo MDF Skirting Board

Price: £0.00Ovolo skirting board is another profile that is widely known and sought... -

Ripple MDF Skirting Board

Price: £0.00Our Ripple skirting board is very different to almost all other skirting in... -

Ripple 2 MDF Skirting Board

Price: £0.00The Ripple 2 is very much a statement moulding. Being extremely bold in its... -

Roux MDF Skirting Board

Price: £0.00Roux is a skirting board design that is exclusive to Skirting 4 U. Since it... -

Square MDF Skirting Board

Price: £0.00Square skirting board continues to be hugely popular with both private and... -

Square Groove MDF Skirting Board

Price: £0.00Square Groove skirting board is another modern profile that has remained... -

Square Groove 2 MDF Skirting Board

Price: £0.00Square Groove 2 skirting board is by far and away the most popular modern... -

Torus 1 MDF Skirting Board

Price: £0.00Our Torus skirting board is an absolute classic MDF moulding design.... -

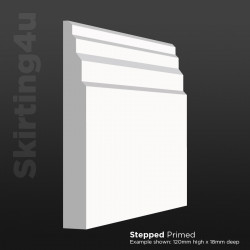

Stepped MDF Skirting Board

Price: £0.00Stepped skirting board is a visually striking design that is a great choice... -

Victorian MDF Skirting Board

Price: £0.00Our Victorian skirting board design is manufactured to sympathetically... -

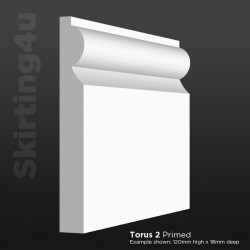

Torus 2 MDF Skirting Board

Price: £0.00Torus skirting boards are by far the most commonly purchased profile we... -

Victorian 2 MDF Skirting Board

Price: £0.00Our Victorian 2 profile is a second variation of a skirting board design... -

Windsor MDF Skirting Board

Price: £0.00Windsor Skirting Board is one of our more exclusive profiles. It is popular... -

Antique 2 MDF Skirting Board

Price: £0.00The Antique 2 Skirting Board profile is a less complex version of our...

Related posts

-

How to Measure and Cut a Skirting Board for an Internal Wall Joint by Bisecting

01/10/201839035 viewsIn this guide, we will showcase how to measure and cut skirting board for an internal wall joint by bisecting an angle.Read more

How to Measure and Cut a Skirting Board for an Internal Wall Joint by Bisecting

01/10/201839035 viewsIn this guide, we will showcase how to measure and cut skirting board for an internal wall joint by bisecting an angle.Read more -

How to Fit Architrave When the Door Frame is Close to the Wall

07/12/201837866 viewsSometimes internal doors are so close to adjacent walls that fitting architrave is difficult. This tutorial will...Read more

How to Fit Architrave When the Door Frame is Close to the Wall

07/12/201837866 viewsSometimes internal doors are so close to adjacent walls that fitting architrave is difficult. This tutorial will...Read more -

How to join two pieces of skirting board together on a flat wall

10/23/201740910 viewsA tutorial showing how to join two pieces of skirting board together on a flat wall.Read more

How to join two pieces of skirting board together on a flat wall

10/23/201740910 viewsA tutorial showing how to join two pieces of skirting board together on a flat wall.Read more -

Step by Step Guide - How to Remove Skirting Board and Architrave

03/29/201739335 viewsA video and written tutorial to show how to remove a skirting board.Read more

Step by Step Guide - How to Remove Skirting Board and Architrave

03/29/201739335 viewsA video and written tutorial to show how to remove a skirting board.Read more -

How to Join Square Groove Skirting Board and Architrave

05/08/201815981 viewsOne of the foremost attractions of the square groove/square groove 2 profiles is that the can be fitted so that the...Read more

How to Join Square Groove Skirting Board and Architrave

05/08/201815981 viewsOne of the foremost attractions of the square groove/square groove 2 profiles is that the can be fitted so that the...Read more